monitoring fibre reinforced plastics

innovation leap:

- innovative textile sensors can monitore fibre reinforced lightweight structures when directly integrated as part of the structure

- strains, movements or vibrations will be detected and measured

- each sensor is made of the same material as the component itself (material conformity) and does prevent from weakening the structure

- sensor area can be freely designed, which allows a load-capable detectionis of frictions (direction)

location of the sensor:

- sensor layer is directly integrated into the core of the fiber-reinforced lightweight components

- this integrative approach is referred to as Direct Material Control, short: DMC

sensoric detection:

strain, stress, natural frequency (resistive)

alternative detection:

fluid levels, proximity sensors (capacitive) and temperature (resistive)

manufactoring process:

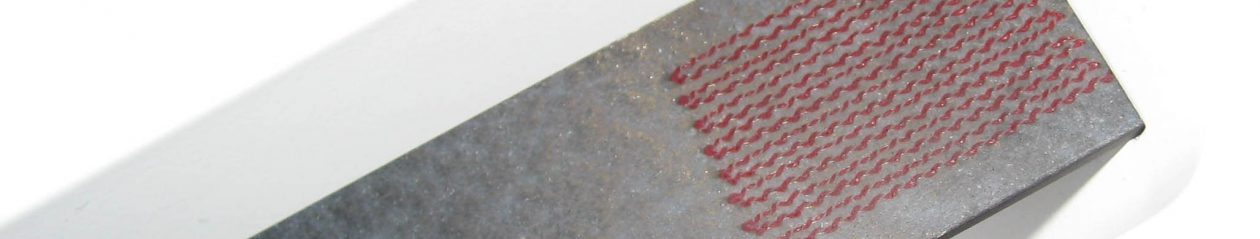

- conventional reinforcement fabrics (for example, woven or nonwoven fabrics made of glass, aramid or carbon) will be embroidered with cunductors (sensor layout)

- in the next step the sensor layer will be directly embedded in (multilayer) fiber reinforced plastics (FRP)

textile technology:

- modified TFP-machines (for tailored fibre placement) and portal systems for contacting and cutting are used

- technology is now referred to as TSP technology (tailored sensor placement)

scalability:

- RTM component for development and testing (individual pieces)

- RTM components (small series composite)

- advanced composites (high volume thermoplastic)

We are happy to provide for further details in personal conversation.