TSP-technology – Tailored Sensor Placement

On this page we give a short introduction to the new developed textile sensors made with innovative Tailored Sensor Placement (TSP).

aims:

- health monitoring basing on signals that derive directly out of defined areas of the fibre reinforced matrix

- signals are also good for measuring and not for detection only

- DMC – direct material control

advantage:

All materials used apply to the matrix of the fibre reinforced structure. Doing so they do prevent from de-lamination of layers or weakening components used inside.

process and technology:

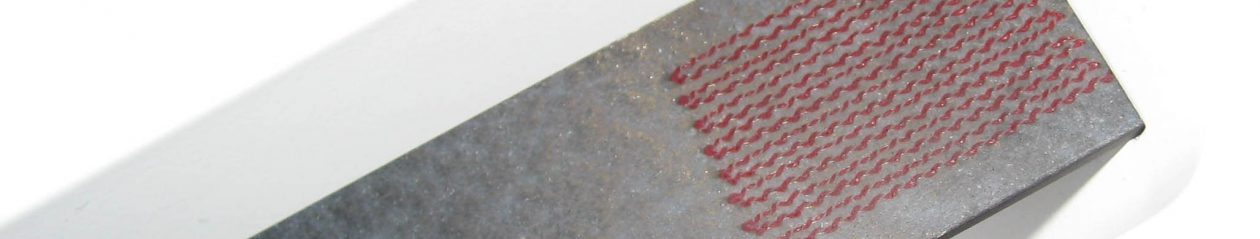

- our system is based on embroidery technology which can add functional components like interconnections and electronic parts to a fabric ground

- the newly developed application technology is called TSP – tailored sensor placement

- TSP connects textiles made of glass, aramid, basalt or carbon with functional structures like sensor areas, feed lines and contact points

- TSP includes also reliable contacts of wires with diameter 0,05 – 0,1 mm, device test and cutting of devices

- next these sensor preforms are suitable for integration in fibre reinforced parts

- possible technologies are RTM for duroplast or dry preforming with thermoplast constructions

usage:

Light weight structures made of fibre reinforced components can directly generate precise sensor signals. This is a new option for structures with need for advanced functional density like device monitoring for security or performance reasons.

fields of application:

- engineering

- mobility sector

- wind power plants

- sports equipment

- health/ medical devices

- construction area

service:

If interested, please contact us. Together with our clients and network partners we develop customized components with high functional density using tailored sensor placement.